Optimel Plåtteknik AB in Uppsala invests in a new S1 Fiber Laser Combi from Salvagnini.

Värnamo, October 2023

Founded in 1997, Optimel is a well-established subcontracting company in the field of sheet metal processing.

Our customers are both large and small companies and we undertake all types of jobs, from mass production to small specialized assignments.

At its core, Optimel has two proprietary brands with products that are constantly evolving to meet the demands of the future.

We carry out stamping, bending, welding, assembly and painting work.

Workshop fittings & mailboxes

Swedish-made workbenches from our own factory in Uppsala. For 14 years, Optimel has been developing workshop interiors together with its customers for car and motorcycle workshops.

Our strength is customized solutions.

Our concept is based on pre-assembled workbenches where you can build virtually any length.

Here we work together to develop a complete solution that is ready to be deployed in your workshop.

The bench concept eliminates the need for expensive and time-consuming assembly in the workshop.

Since the start in 1989 with the first large weekly mailbox on the Swedish market, we have continued to develop our range of mailboxes.

We constantly strive to deliver premium products with good solutions adapted to the current and future needs of the mailbox and parcel box segment.

With BOX, we are well prepared for future e-commerce logistics.

The digital lock from Inside The Box gives you many future uses for your mailbox.

Swedish-made mailboxes in our own factory are a matter of course for us and our aim is to have 100% satisfied customers.

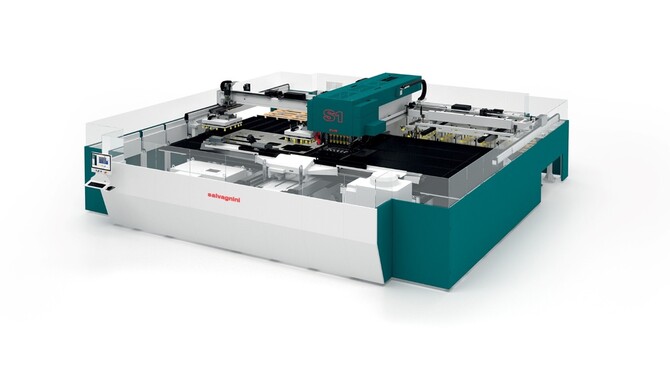

Now we take the step and invest in a new Salvagnini S1 Punching fiber laser combi is a new proprietary with patented hybrid system with only a few liters of oil in a closed system.

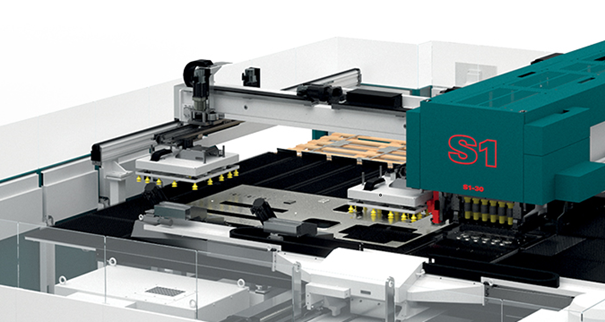

S1 is unique with Salvagnini’s well-proven multi-press head where all punches are always pre-punched, this means that there are no changeover times between different punches. The S1 can hold up to 59 different tools in the multi-press head and 6 different threading stations located next to the punch head. This, together with the fiber laser head, makes the S1 the complete and compact combination machine.

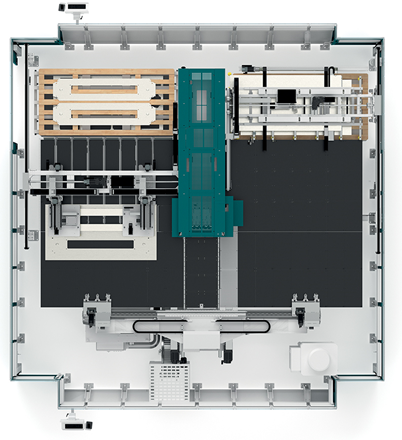

In terms of layout, the entire facility takes up only 7×8 meters, including both incoming materials and the sorting and handling of skeletons.

Sorting is done with Salvagnini TM which is a further development of the MCU available for both Stans S4 and Fiberlaser L5/L3. TM is equipped with both suction cups combined with magnets and can either work separately or together, hence there are no limitations on the maximum dimensions of outgoing parts. Small details are handled through the hatch for sorting into different boxes.

The entire plant will be installed in the fall of 2023, making it the 1st in Sweden.

Salvagnini thanks Fredrik, Andrea and Lars for their trust and welcomes you to the Salvagnini family.